For the HAPT project, researchers are working on a test bench for the future development of reliable turbine blade bearings.

Blade bearings might not exactly be the most expensive components in a wind turbine, but damage to this fundamental part of the system can result in considerable downtimes and costs. By designing and testing blade bearings under realistic conditions reliable operation of future turbines shall be improved.

In the HAPT research project (short for “Highly Accelerated Pitch Bearing Test”) researchers from the Fraunhofer Institute for Wind Energy and Energy System Technology, IWES Nordwest, and the Institute of Machine Elements, Engineering Design, and Tribology (IMKT) at Leibniz Universität Hannover, work together with the IMO group to establish the foundations for the further development of blade bearings.

The German Federal Ministry for Economic Affairs and Energy (BMWi) provided funding for the project to the tune of 10.7 million euros.

The aim is that the project results will allow the use of individual pitch-control systems for load reduction, which is the primary goal of the manufacturers. In wind turbines in the 7 to 10-MW range, the wind drives blades of up to 80 m in length. Blade bearings, the interface between the hub, and the blades, are the design bottle-neck in the development of systems of this size. Because of the sheer dimensions of the blades, the systems are subject to effects that can be already detected in turbines with smaller dimensions but are not all that significant.

As the load increases, faults in the blade bearings increase exponentially, as does the rate of damage. But almost no information is available on how and why these faults develop. As a result, experience-based design of blade bearings, which is standard practice among manufacturers, is now reaching its limits.

One possibility for reducing the loads to which the structure of the wind turbines is subject is individual pitch control (IPC), which balances out the loads across the individual blades and reduces them overall. However, as there is still no reliable information available concerning the suitability of blade bearings for the use of IPC and because the latter further increases the demands placed on the blade bearings, the industry sector remains somewhat hesitant to introduce this seminal technology.

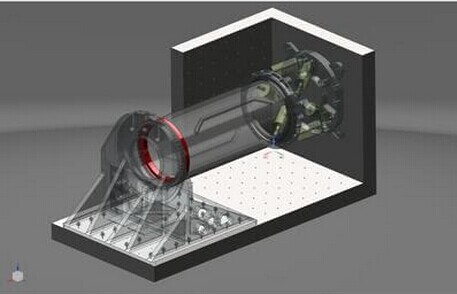

The researchers involved in the HAPT project want to resolve these uncertainties by developing a test bench for blade bearings and a method for calculating their service life. Accelerated testing procedures should make it possible to simulate 20 years of operation in a testing period of just six months.

“According to our strategy we contribute method expertise of testing wind-turbine components,” comments deputy director Prof. Dr. Jan Wenske the IWES’ share. The aim is to provide the industry with the necessary prerequisites for the computational design of blade bearings – dimensioning will become more precise, the use of IPC will be made reliably possible and levelized cost of electricity will be cut at the same time.

IMO Head of Engineering Hubertus Frank is confident: “The new testing opportunities of HAPT will establish a new basis for the development of future blade bearings. We will provide blade bearings and a wealth of practical know-how for the tests.”

Prof. Dr.-Ing. Gerhard Poll of the Leibniz Universität Hannover sees beneficial effects: “I expect this project to bring together the competencies of Fraunhofer IWES, Leibniz Universität Hannover, and thereby ForWind, in an exemplary way. Along with IMO Group the wind turbine technology will make a big step forward.”

The results of the project will be incorporated in the future standardization of blade bearings.

For the HAPT project, researchers are working on a test bench for the future development of reliable turbine blade bearings.

Blade bearings might not exactly be the most expensive components in a wind turbine, but damage to this fundamental part of the system can result in considerable downtimes and costs. By designing and testing blade bearings under realistic conditions reliable operation of future turbines shall be improved.

In the HAPT research project (short for “Highly Accelerated Pitch Bearing Test”) researchers from the Fraunhofer Institute for Wind Energy and Energy System Technology, IWES Nordwest, and the Institute of Machine Elements, Engineering Design, and Tribology (IMKT) at Leibniz Universität Hannover, work together with the IMO group to establish the foundations for the further development of blade bearings.

The German Federal Ministry for Economic Affairs and Energy (BMWi) provided funding for the project to the tune of 10.7 million euros.

The aim is that the project results will allow the use of individual pitch-control systems for load reduction, which is the primary goal of the manufacturers. In wind turbines in the 7 to 10-MW range, the wind drives blades of up to 80 m in length. Blade bearings, the interface between the hub, and the blades, are the design bottle-neck in the development of systems of this size. Because of the sheer dimensions of the blades, the systems are subject to effects that can be already detected in turbines with smaller dimensions but are not all that significant.

As the load increases, faults in the blade bearings increase exponentially, as does the rate of damage. But almost no information is available on how and why these faults develop. As a result, experience-based design of blade bearings, which is standard practice among manufacturers, is now reaching its limits.

One possibility for reducing the loads to which the structure of the wind turbines is subject is individual pitch control (IPC), which balances out the loads across the individual blades and reduces them overall. However, as there is still no reliable information available concerning the suitability of blade bearings for the use of IPC and because the latter further increases the demands placed on the blade bearings, the industry sector remains somewhat hesitant to introduce this seminal technology.

The researchers involved in the HAPT project want to resolve these uncertainties by developing a test bench for blade bearings and a method for calculating their service life. Accelerated testing procedures should make it possible to simulate 20 years of operation in a testing period of just six months.

“According to our strategy we contribute method expertise of testing wind-turbine components,” comments deputy director Prof. Dr. Jan Wenske the IWES’ share. The aim is to provide the industry with the necessary prerequisites for the computational design of blade bearings – dimensioning will become more precise, the use of IPC will be made reliably possible and levelized cost of electricity will be cut at the same time.

IMO Head of Engineering Hubertus Frank is confident: “The new testing opportunities of HAPT will establish a new basis for the development of future blade bearings. We will provide blade bearings and a wealth of practical know-how for the tests.”

Prof. Dr.-Ing. Gerhard Poll of the Leibniz Universität Hannover sees beneficial effects: “I expect this project to bring together the competencies of Fraunhofer IWES, Leibniz Universität Hannover, and thereby ForWind, in an exemplary way. Along with IMO Group the wind turbine technology will make a big step forward.”

The results of the project will be incorporated in the future standardization of blade bearings.

Tel:86-21-55155796;86-21-63563197

Fax:86-21-63561543

Address:No. 3978, Baoan Highway, Anting Town, Jiading District, Shanghai

Email:wf@wfbearings.com

Website:www.csjhhbgc.com www.wfbearings.com

Mobile Site

Mobile Site